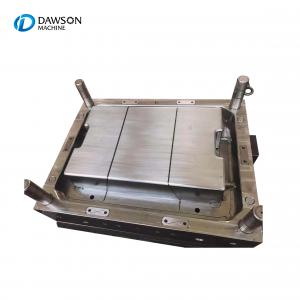

lubricating oil bottles, daily chemical products bottles, cosmetics bottles, chemical barrels, auto parts, etc; There is not only

a professional team, but also a highly configured production workshop to provide customers with the highest quality blow molding

molds and complete plastic products solutions, including blow molding machines, auxiliary machines and automatic packaging lines.