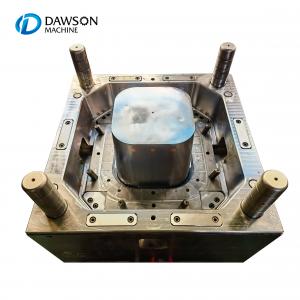

Chinese manufacturers new mold plastic drum Paint bucket injection molding mould

Our customers are all around the world.

Vietnam, Australia, Indonesia, Malaysia, Thailand, Sri Lanka, Kazakhstan, Russia, UAE, Saudi Arabia, Malta, Romania, Italy, India,

Syria, Ethiopia, Egypt, Sudan, Tunisia, Algeria, Kenya, Nigeria, South Africa, Zimbabwe, Mexico, Guatemala, Ecuador, Colombia,

Venezuela, Peru....

DAWSON MACHINE & MOULD GROUP is a professional plastic injection mould maker and custom plastic parts manufacturer.

We can make all kinds of plastic injection mould including daily use mould, auto part and motor part mould, home appliance mould,

automotive mould, and industrial product mould.

We have lots of experience in making customized plastic injection mould.

Send us the inquiry with drawing and requirement (steel raw material, cavity no. etc) for mould, we will reply you within 24 hours

and quote for you within 2 working days.

| 1. Mould cavity & Cutting edges use high quality Stainless steel S136H, which is the best material for blowing moulds. |

| 2. Our necking plate is using imported JAPAN material DC53,Heat treatment to HRC62. |

| 3. Our cooling system is covered very average,all the necking area, handle area had designed perfect cooling system to make sure

long time smooth running. |

| 4. Our de-flashing unit and mask material is using High quality Aluminium alloy 6061#. |

| 5. De-flashing cylinder all use high quality Taiwan AIRTAC cylinder. |

DAWSON MACHINERY & MOULD GROUP

Product Description

Below is the general information and policy for our OEM/ODM plastic injection mold:

| Dawson preform MOLD ----mold parts details |

| Name | Description | Name | Description |

| Cavity | Hardness : 50-52HRC

Marterial:S136 / P20

Choose spiral cooling water design , Ensure preform have good cooling effect | Core | Hardness: 50-52HRC

Marterial:S136 / P20

Big cooling water road design ,Ensure preform have good cooling effect. |

| Mold base | Hardness: 30-32HRC

Marterial:national standard P20

Graphite copper plate insert, has a good lubrication effect. | Thread | Hardness: 50-52HRC

Marterial:S136 / P20

Independent cooling water is used. Add pin nails. Ensure high quality molding |

Nozzle

holder | Hardness: 53-55HRC

Material :SKD61 | Nozzle | Hardness:38- 40HRC Material: Beryllium Copper+coating After coating hardness more than 70HRC |

| Mini coil heater | Voltage:240V

Energy Consumption:268W

The heater function of the new structure can prevent the waste of heater and save half the energy. | Valve pin | Hardness :59° - 61°Material:SKH51.

Same as Husky craft

High hardness, High ductility, High grinding

resistance and High heat resistance. |

| Insulator | Dupont Brand material from USA. | Thermo couple | America OMG brand (double pin ) |

| according cap design choose finally mould design |

DAWSON Mould Trade Process:

| 1. Quote | According to sample, drawing and specific requirement. |

| 2. Discussion | Mold material, cavity number, price, runner, payment, etc. |

| 3. S/C Signature | Approval for all the items |

| 4. Advance | Pay 50% by T/T |

| 5. Product Design Checking | Our engineers will check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

| 6. Mould Design | We make mould design on the basis of confirmed product design, and send to customer for confirmation. |

| 7. Mold Tooling | We start to make mold after mold design confirmed |

| 8. Mold Processing | Send report to customer once each week |

| 9. Mold Testing | Send trial samples and try-out report to customer for confirmation |

| 10. Mold Modification | According to customer's feedback |

| 11. Balance settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

| 12. Delivery | Delivery by sea or air. The forwarder can be designated by your side. |

Why choose us?

| 1. | Best design,competitive price |

| 2. | More than 10 years experience in this field |

| 3. | Professional in design & making plastic mould |

| 4. | One stop solution |

| 5. | On time delivery |

| 6. | Best after-sale service |

| 7. | Specialized in all kinds of plastic injection moulds |

DAWSON can offer you:

1.Good steel with high hardness

2.Good accessories with high brightness

3.Good machining with high precise

4.In-time response on email, telephone calls or fax

5.In-time supply the quotation and mould designs

6.In-time commnication on the technical points

7.In-time sending pictures for the mould machining progress and mould finishing schedule

8.In-time mould test and sample delivery

9.In-time mould delivery

About mould material:

We make the commitment of service as below:

1.Lead time: 30-50 working days

2.Design period: 1-5 working days

3.Email reply: within 24 hours

4.Quotation: within 2 working days

5.Customer complaints: reply within 12 hours

6.Phone call service: 24H/7D/365D

7.Spare parts: 30%, 50%, 100%, according to specific requirement

8.Free sample: according to specific requirement

We guarantee to provide the best and quick mold service for customers!

Our professional blow molding machine workshop...

High Quality Mould

In the process of plastic blow molding, the mold is a very important part. A good blow mould can make the product production more smoothly, and a good blowing mold can also make the finished product more flexible and beautiful.

We have our own mold production workshop, using high configuration equipment and mold engineers with 16 years of technical experience to customize blow molding mold for you.

- We use the best stainless steel S136H or Aluminium alloy 7075# as mould main material- Necking plate use JAPAN DC53 Heat

treatment to HRC62

- Double neck design available to change in future as a spare part necking

- All mould can be made auto-deflashing or manual deflashing as per customer requests

- Perfect mould cooling design to ensure the best moulding preformace

- Available to provide 2D & 3D product drawing for customers

- Available to send samples to customer for approval the product quality

- We had already made moulds for TOTAL,SHELL,GULF,BMW,YAMAHA,MOBIL,TOYOTA,MENGNIU, HYUNDAI,MENTHOLATUM,UNILEVER,LEE KUM KEE...

DAWSON MACHINERY & MOULD GROUP

Our customers are all around the world.

Vietnam, Australia, Indonesia, Malaysia, Thailand, Sri Lanka, Kazakhstan, Russia, UAE, Saudi Arabia, Malta, Romania, Italy, India, Syria, Ethiopia, Egypt, Sudan, Tunisia, Algeria, Kenya, Nigeria, South Africa, Zimbabwe, Mexico, Guatemala, Ecuador, Colombia, Venezuela, Peru....

We have our own service team in

Saudi Arabia, Colombia, Panama, South Africa ...

DAWSON MACHINE & MOULD GROUP

located in Zhangjiagang city, have more than 18 years' experience in the field of plastic machinery,

blow molding machine, injection molding machine, PET blow molding machine, injection blow molding machine, during the past 18 years, we always force our energy into new areas of plastic machinery, plastic packaging machinery, to update the technology, to learn advanced experience,

to confirm new theory and new design, we are forming a unique competitive advantage of our owns.

The machines from our company carry good quality and effective after-sales service, upon the market,

customers from more than 45 countries, we provide complete solution for your plastic industry

business, as well as all sorts of technical support & after-sale services!

DAWSON will be your reliable friend in China, and we will always do our best to give you max support!